(short description of the project + goals)

- Toothpaste tablets – order ingredients for first formulation?

I’ve found out the following things:

- Fluoride is hard to get in small quantities and/or as a consumer

- The type of fluoride matters

- Soluble calcium in the formulation reacts with fluoride to give insoluble calcium fluoride, making it less effective unless you don’t rinse and drink anything for several hours after

If I want the best fluoride action, I should get soluble sodium fluoride, and I should not use calcium compounds as the abrasive. This is why the toothpaste tablets I buy from the store have cellulose and silicate instead of calcium carbonate, I think.

I could spend €20 to get 100 grams of sodium fluoride which would last me a lifetime, but I’d prefer to not have so much of a toxic compound in a drawer so I’m continuing to look for smaller quantities.

Cellulose (microcrystalline cellulose, MCC, E460): this is also less abrasive than most other most other toothpaste binders. I can’t find a good source for buying it yet.

Sources for what ingredients to use: this study, this site

Mild abrasives

- Calcium carbonate – makes fluoride less effective (Mohs 3.0)

- Sodium bicarbonate – more of a filler, not abrasive enough on its own (Mohs 2.5)

- Magnesium carbonate – also makes fluoride less effective, but magnesium fluoride is slightly more soluble (Mohs 4.0-4.5)

- Dehydrated silica gels – too hard/abrasive (Mohs 7 vs enamel’s 5)

- Silicates – too hard/abrasive

- Hydrated aluminium oxides – I don’t want aluminium, also way too hard (Mohs 9)

- Phosphate salts

- Dicalcium phosphate dihydrate (DCPD, Mohs 3.5) – fluoride interaction? It is compatible with monofluorophosphate (MFP). Can find as animal feed and bulking supplement, but this is typically the much harder anhydrous form (DCPA), so I would need to hydrate it. That’s ok, I need to add water to make a slurry anyway. Calculate how much DCPA is needed, calculate how much water is needed to hydrate 100%, calculate how much extra water is needed for formulation, soak overnight, filter and dry back to required weight. May not have same properties as commercial DCPD, which I was able to find here (food grade)

- insoluble sodium metaphosphate (IMP)

sodium hexametaphosphate. Edit: sodium hexametaphosphate (SHMP) is not used as abrasive, but as a soluble active ingredient that helps prevent staining and tartar – best used around 0.25% because then it also prevents tooth erosion, with possible negative effects.

- Natural materials: cedar nut shell powder, walnut shell powder, olive stone powder, almond shell powder, pistachio shell powder, pear stone powder, etc. all have a Mohs hardness around 3.5 – ideal hardness for a mild tooth abrasive. However, may be hard to find in the right size (<100µm, possibly smaller needed), may contain pigments that stain, may require rinsing after brushing

Thickening agents

- Mineral colloids, e.g. clay

- Seaweed colloids e.g. carrageenan

- Natural gums

- Cellulose gum; Carboxymethyl cellulose (CMC)

- Hydroxyethylcellulose (HEC)?

- Xanthan gum

- Synthetic cellulose

- Microcrystalline cellulose (MCC)?

Other stuff:

- Xylitol – active ingredient, sweetener. 25% is ideal

- Surfactant: SDS, SLS (anionic, don’t want), sodium cocoyl glutamate (anionic), cocamidopropyl betaine (amphoteric), lauryl glucoside (nonionic), coco glucoside (nonionic). Nonionic is mildest on salivary pellicles

- Fluoride: I want sodium fluoride or sodium monofluorophosphate (MFP)

- Zinc (zinc chloride 47.98%, zinc citrate 22.77%, zinc acetate 35.64%, zinc gluconate 13.29%): inhibits plaque formation, prevents halitosis. Allowed up to 1%, although there was a proposal to lower this to 0.1% for toothpaste but in this study 1% was deemed to be perfectly safe. I’m finding it difficult to find any food safe soluble zinc powder as a consumer though. Perhaps zinc oxide (80.35%, Mohs 4.5) works ok? Colgate uses it. However, not very soluble.

- Cream of tartar (potassium bitartrate): antimicrobial, flavour, helps hold the tablets together

- Citric acid: stimulates saliva production, pH balancing

I’ve decided that calcium carbonate base would still be the easiest, even if it makes the fluoride less effective. Many toothpaste products still combine these two.

Total formulation:- 50% calcium carbonate – 500 g makes 2.0 kg for €6.88

- 20% sodium bicarbonate – 454 g makes 2.3 kg for €1.70

- 25% xylitol – 300 g makes 1.2 kg for €4.99

- 2% coco glucoside – 250 mL makes 12 kg for €4.75

- 1.5% coco betaine – 250 mL makes 16 kg for €4.45

- 1.2% zinc oxide – 100 g makes 8.3 kg for €4.55

- 0.3% sodium fluoride – 100 g makes 33 kg for €21.12

- up to 0.25% essential oils to taste

plus water, approx. 20%

With each tablet being about 0.3 to 0.5 g, this set of ingredients would make me about 3000 tablets for €48.44 (€0.016 each), compared to about €0.042 each at the store. Including the €5.99 silicone mould the break even point for 1 person is about 2 years worth of toothpaste tablets (~1500).

The surfactants I only need very little of, and I’m already buying them for other products, so I guess the total cost for this project is a little lower. The zinc oxide and sodium fluoride I will have way too much of, but the calcium carbonate, sodium bicarbonate and xylitol are easy to get more of so if I really wanted to I could make 20,000 tablets for around €100 (€0.005 each) which would last me about 27 years.

- Toothpaste tablet mould & shampoo bar mould

I ordered some items that I hope to be able to use as moulds.

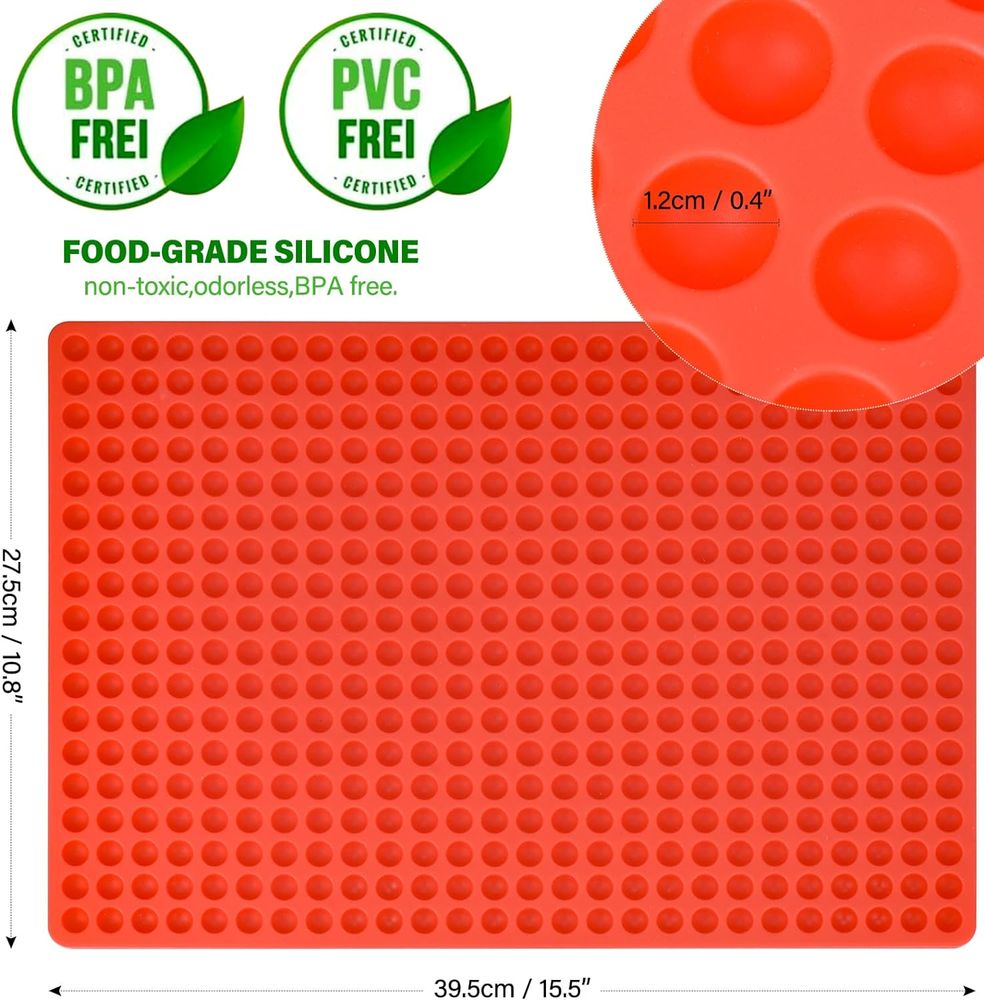

The first is a pet treat baking mould that I hope to use for making toothpaste tablets. It’s made out of food-grade silicone and has 468 “hemispheres” of 12mm diameter. They’re not entirely pill-shaped so I hope it works! I looked up toothpaste tablet sizes and apparently they range from about 8mm to about 12mm so I guess it should be about the right size.

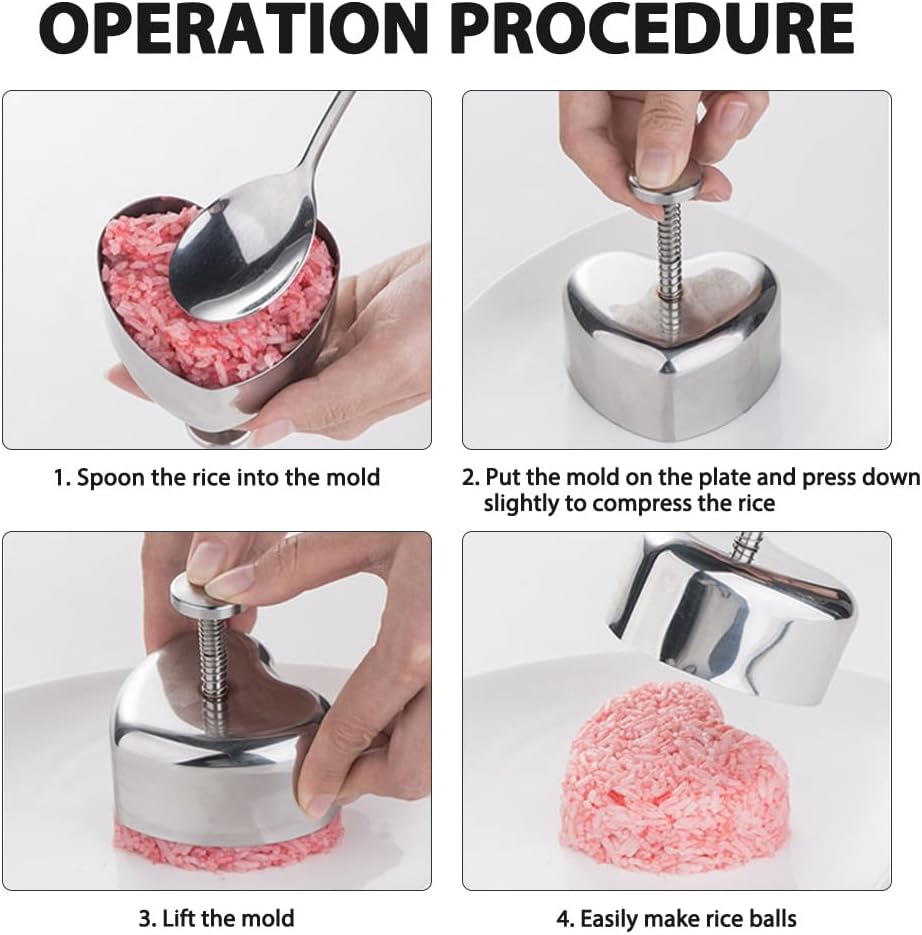

The second item is a pair of Onigiri rice ball presses that I hope to use for making shampoo bars. Again I don’t know if it’ll work, but apparently some people have had success with them. The shampoo bars I buy from the store are 6cm diameter, 3cm thickness, 65g, but I wouldn’t mind them to be a bit bigger. The rice ball press is about 7.5×9.5cm so a little bigger but I think it would still be a nice size.

- Toothpaste tablets

I like using toothpaste tablets but they’re expensive and the store where I get them doesn’t always have them in stock. Recipe: Xylitol, Microchrystalline Cellulose BP, Dicalcium Phosphate Dihydrate, Sodium Bicarbonate, Sodium Lauryl Sulfoacetate, Mint Powder, Menthol, Sodium Fluoride.

Maybe this recipe?

Maybe use hydroxyethylcellulose? About 1%? The brand I’m currently using containts microcrystalline cellulose (MCC), and some brands contain up to 70% MCC. I can’t find any good sources for MCC, I guess calcium carbonate has the same function.