We have several Edmund Bühler VKS75 orbital shakers at our lab, at least one of them is older than I am. They are very large capacity (up to 75 kg depending on rpm) shakers, and we have them as single, double and triple platform ones. They are very sturdy machines that are supposed to last nearly forever, but lately they have been breaking down at an alarming rate.

At first I thought it was because they were overloaded; one of our students was loading a lot of them full of 500 mL square bottles. But I checked and no, this was well within the machine’s capacity. I checked with Edmund Bühler and they confirmed, the weight shouldn’t be a problem. But the machines were shaking on their feet, making noise, and sometimes they tended to shake themselves across the room. And they were breaking down more often than they should.

I checked if the machines were installed level. Turns out, the floor in the room they’re in is far from level. My predecessor, whom I inherited responsibility over the machines from, had apparently attempted to solve this by levelling the machines with rubber pads. Or perhaps those were intended to prevent the shakers from walking around the room? I now think that this extra rubber was a big part of the problem; the shaking motion compressed the rubber, magnifying the movement of the entire machine. This was mainly a problem with the tall 3-story ones. The machines already come with rubber feet, I suppose they are specifically sized to dampen the movements and any extra rubber probably makes things worse.

Anyway, the machines’ feet are not height adjustable, so I bought some 50×50 mm plastic levelling tiles in different thicknesses to replace the rubber pads. The floor is really wonky. With some machines, there was up to 7 mm difference from one foot to another to get the machine level, but I only had tiles up to 5 mm thick. I levelled them as best as I could and it was a big improvement over the rubber pads. The machines were no longer making ominous noises, and compared to with the rubber pads they were barely moving any more.

But one of the shakers still managed to shake itself off its little levelling tiles the day after I levelled it, so back to the drawing board..

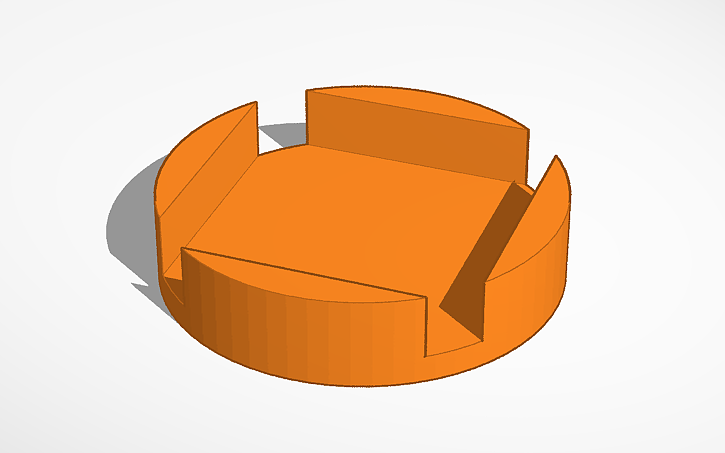

I designed a simple levelling tile holding foot, and had a set of them 3D printed with 100% infill. It’s a round puck, with a square recess for the tiles such that you can easily get them out by the corners. It’s tall enough that I can stack multiple tiles to make up the 7 mm floor difference without the shaker shaking itself off, but low enough that you don’t have to lift the machine very far to put the feet under.

So far, it seems to work really well! I love simple solutions :)