Humidity in my room is really starting to be a problem with all the plants I’ve got, and I haven’t even started up my active hydroponics systems or moss poles.

In a previous post, I looked at heat recovery ventilation to remove humidity without losing or gaining too much heat. I wrote that a ductless in/out “recuperator ventilation” system would be easiest/cheapest. Some thoughts:

- Efficiency is low, closer to 50% than the claimed 80-90%

- Decent units start around €300. Would be cheaper to just heat more and open the window in winter, or run a dehumidifier, though those wouldn’t solve hot & humid summer problems

- DIY would be difficult, because of the fan; most modern fans (including PC fans) can only run in 1 direction

- Soundproofing is difficult

So I’m going back to a counterflow heat exchanger idea. I previously looked at using a Stork heat exchanger unit, or perhaps repurposing only its core. However, that would be way too big for just my room, so I’m looking at making a smaller heat exchanger myself. I would still like it to be as efficient as possible. Main things that influence efficiency:

- Surface area of heat exchange

- Thickness of material

- Thermal conductivity of material

Maximum surface area is dictated by shape/construction of the exchanger and static pressure performance of the fans. To improve the other variables, I should use a material like copper aluminium, that is as thin as possible. I’m thinking aluminium foil like this DIY design that uses stacked panels clad in aluminium foil, or this design that uses 0.5mm aluminium sheeting folded in a zig-zag pattern.

I really like the aluminium foil panel design, but I should take care that condensation does not cause issues e.g. with mould, so I don’t think I should mount the foil on wooden frames. Perhaps something 3D printed could work. I would also use thicker industrial grade foil instead of household foil.

I should think about the space that is available, and how I can fit the core, insulation, fans, filters, perhaps a sound baffle etc. into that. Ideally have the two outlets as far apart as possible to prevent short circuiting, both inside the room and outside the window.

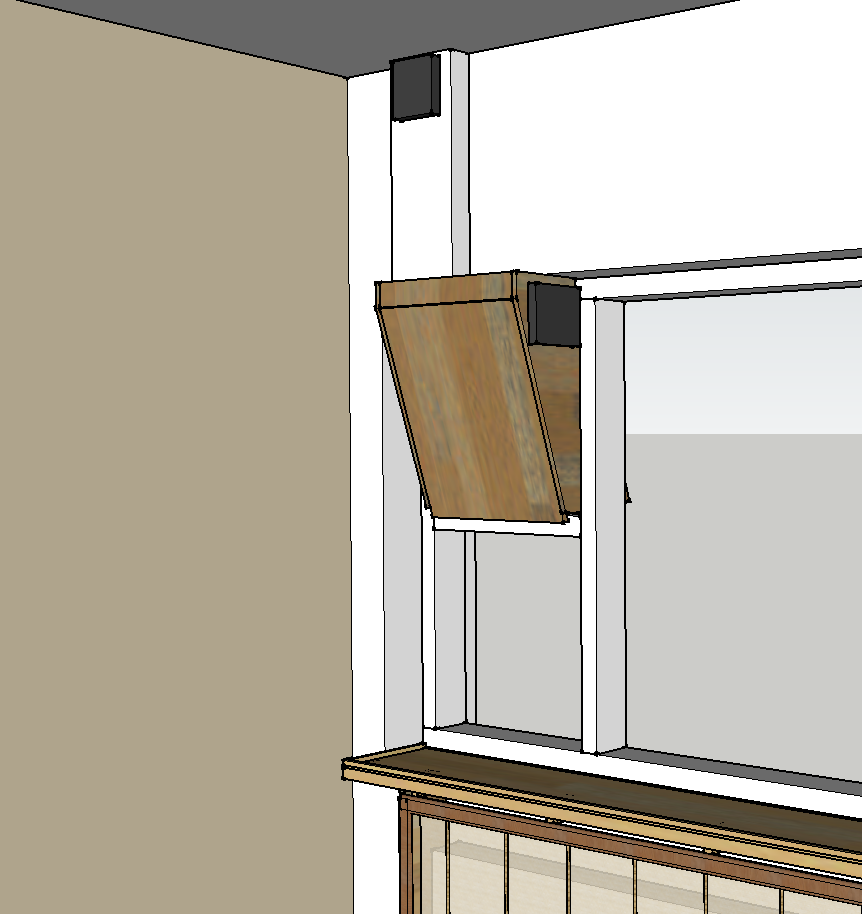

Here’s a first sketch of a compact unit using a 50x30x12cm core, clad in 4cm insulation and surrounded by a plywood shell that fits in the window opening. One 140mm fan would be mounted near the ceiling on a 220x54mm duct, while the other would come out sideways by the window. Or perhaps I could mount both fans on the housing and/or run the duct further out. The core would be made of 16 panels, each constructed out of 7.5mm PVC U-profile with slits for passing the air in between the foil.

To be continued.